The latest advances in radiation-hardened digital components have enabled the development of MCXOs that, for the first time, can replace larger, high-power-consuming OCXOs in low-earth orbit (LEO) New Space applications

Introduction

The last post in this series explored the benefits of microcomputer-compensated crystal oscillators (MCXOs) when compared to (oven-controlled) OCXOs. This post introduces the first MCXO that combines clever engineering design with rad-hardened digital components to qualify for New Space applications.

Developing Space-Qualified MCXOs

When developing MCXOs in the early 2000s, the space- and rad hard-level digital components needed were very expensive, which meant an MCXO space-level product would sell for hundreds of thousands of dollars each.

At the dawn of the era of mega satellite constellations, known as low-earth orbit (LEO), or New Space, it became possible to find microcontrollers and other digital devices that were rad tolerant and up-screenable. The use of these digital components went into the QT2020 MCXO (Figure 1), released in 2021, which has now been fully qualified for use in LEO New Space applications.

Figure 1. The small, light (21” x 1.33” x 0.33”) low-power-consumption QT2020 MCXO.

The QT2020 MCXO was designed with the objective of use in satellites and other space applications, using only rad-tolerant components. The product series is available at 10, 20, 30, 40, 50 60, or 80 MHz, with stability as low as ±10 PPB in a 2-inch by 1-inch by 0.33-inch package. And it offers the high performance of an OCXO but with less than 90mW power consumption.

The QT2020 MCXO is now a standard product that can be procured without difficulty and at a reasonable cost. Prices vary based on the stability and other options. For instance, a full totally RAD-hard version can be developed if the application will support a higher price.

The QT2020 MCXO has been tested for TID up to 50 kRADs without experiencing problems, and the current consumption level was “rock steady” as the radiation dosage went up – giving optimism that single-event results will be good. Now, single-event testing is being arranged.

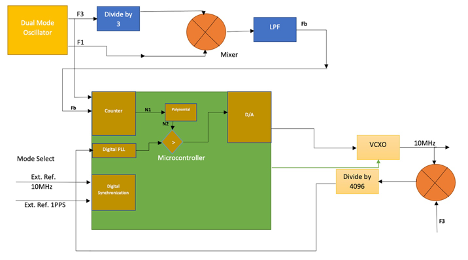

Figure 2 shows a simplified block diagram of the QT2020 MCXO. The signals from dual mode oscillator get mixed down to generate beat frequency after been normalized by a frequency divider. The beat frequency is a difference between two oscillator modes and represent the crystal temperature. It feeds the microcontroller counter to generate digital temperature reading “N1.” Data for N1 is collected and stored in microcontroller memory. For each N1, a polynomials calculation provides correction coefficient “N2.” A 10MHz VCXO provides the signal to one of the microcontroller counters to get compared to Fo signal. N2 correction is applied here. A Digital to Analog converter applies a control voltage to the VCXO to keep it at the target frequency.

Figure 2. Simplified block diagram of the QT2020 MCXO.

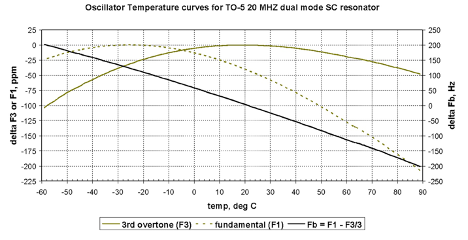

The chart in Figure 3 shows how the dual-mode SC cut crystal functions as a self-sensing thermometer. The dashed curved line is the frequency vs temperature curve for the crystal’s fundamental mode, and the continuous curved line is the frequency vs temperature curve for the crystal’s third overtone. When the oscillator is measured at any given temperature, the reading for the third overtone (divided by 10) is divided by the reading for the fundamental, and the resulting ratio is called the Beat Frequency and it falls on the straight line. This shows exactly at what temperature the crystal is at that time since the particular crystal in question has been precisely characterized for how its Beat Frequency varies linearly with temperature.

Major performance characteristics for the QT2020 MCXO show that it is considerably better for size, weight, power consumption, and warm-up time than any OCXO and is considerably better for frequency stability than any TCXO.

Figure 3. The QT2020 MCXO’s performance characteristics.

Conclusion

The QT2020 MCXO fills a niche with much better stability than the best TCXO and offers the equivalent stability and noise to typical OCXOs. It also has extremely low power consumption, small size, fast warm-up, and is fully certified and rated up to 50 kRADs TID. Time will tell, but this rad-hardened MCXO promises to be a revolutionary, enabling technology. Already, many satellite manufacturers are placing orders, evaluating the product, and planning to fly the QT2020 MCXO in exciting New Space applications.