Commercial grade quartz crystal oscillators can sometimes exhibit problems known as “activity dips” that occur only at very specific temperatures. If you never happen to operate at exactly the problem temperature, you will never see the problem.

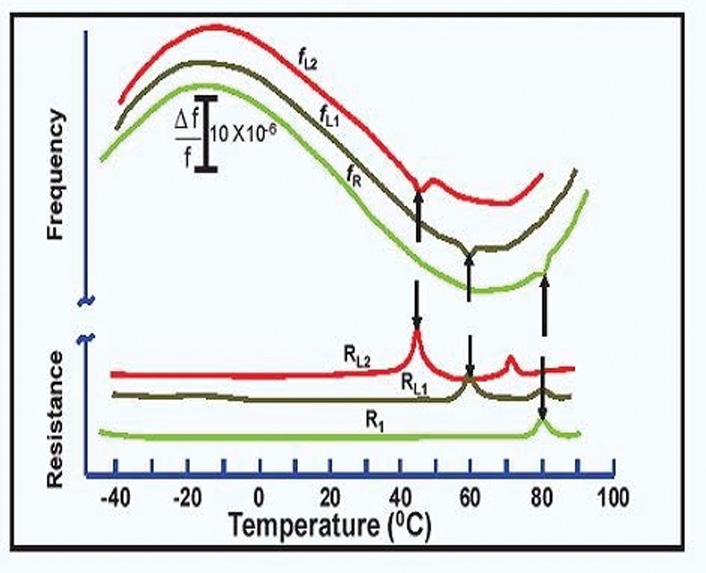

But what is an activity dip? It’s a relatively sudden increase in the crystal’s resistance, (a perturbation) in the quartz crystal’s series resistance and frequency characteristics over temperature. Generally, activity dips are caused by an interfering mode of vibration (coupled mode) in the quartz crystal. A coupled mode bleeds energy from the main mode if and when its frequency coincides with the frequency of the main mode, sharply increasing the resistance of the main mode. An activity dip can cause a system to lose phase lock or other types of problems.

These interfering modes are actually high overtones (up to the 50th overtone) of low frequency flexure modes. They have a very steep temperature coefficient of about -20 ppm/°C. They only coincide with the main mode frequency for a narrow temperature range, roughly 5 to 20°C wide. If an interfering coupled mode is not designed out an activity dip will result in this temperature range.

Because a coupled mode is quartz based, it causes any activity dip to be very repeatable over time and temperature. The magnitude of the effect of a coupled mode can range from minor to intermittent to catastrophic. It all depends on the strength of the interfering mode and how sensitive the application is to changes in oscillator output level and frequency shifts of 2 to 20 ppm.

Another cause of activity dip is a particle stuck on or near to the active area of the crystal. This type of activity dip can change with time and temperature. These dips would be affected if the particle becomes detached from the crystals surface or moves to another position on the surface. This position change could cause the dip to get better, worse of disappear at least temporarily. Or go from not detected to suddenly occurring or changing the magnitude at the temperature the dip occurs.

Some considerations for designing an AT-cut activity dips-free quartz oscillator:

1) Quartz processing and manufacturing:

- Physical geometry of the crystal unit design

- Electrode parameters and design (R1, C1, C0, L1)

- Load capacitance

- Drive level and drive level dependency (DLD)

- Particles introduced during base or final plating

- Contaminants such as oil from vacuum pumps

- Scratch(es) on the crystal blank

- Crystal cut and operating mode

- Method of mounting

- Operating temperature window

Click here to download Q-Tech’s Activity Dips Application Note